Nondestructive Testing (NDT) plays an important role in assuring that structural and mechanical components perform their function in a safe, reliable, and cost-effective manner. NDT is typically used at various points in a part’s life cycle. NDT can be used prior to the use of a component for the sake of quality control. NDT is also employed while components are in use to detect service-related conditions caused by wear, fatigue, corrosion, stress, or other factors which affect reliability.

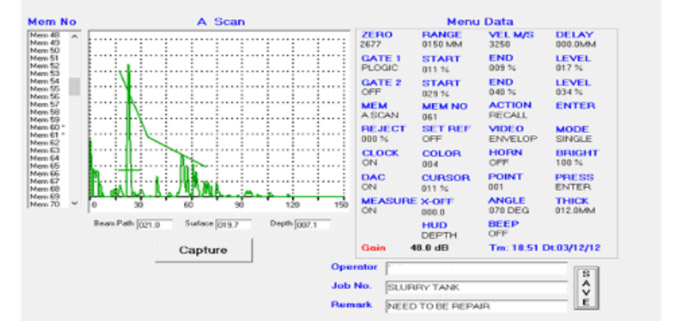

In ultrasonic testing, very short ultrasonic pulse-waves with center frequencies ranging from 0. 1-15 MHz and occasionally up to 50 MHz are launched into materials to detect internal flaws or to characterize materials.

The Magnetic Particle Inspection method of Non-Destructive testing is a method for locating surface and sub-surface discontinuities in ferromagnetic material.

Radiography uses and x-ray device or radioactive isotope as a source of radiation which passes through the material and is captured on film or digital device.